Services

Our CNC machining services offer a wide range of capabilities for producing complex assemblies with unmatched quality. Our equipment set includes a 5-axis CNC high-speed precision turning center equipped with 21 tools, an automated bar feeder, and tool monitoring. These features enable us to efficiently produce small prototypes or large volume runs, with less time and handling, without compromising on quality.

Our value-added services provide us with the flexibility to integrate many additional services with our precision machining and manufacturing to meet our customers' unique requirements. These services allow us to provide a one-stop shop for our customers, where they can have all their needs met by one supplier, making it more convenient for them to focus on their core business activities. We can handle a wide range of materials, including aluminum, brass, copper, stainless steel, titanium, and many others. Our team of skilled machinists and engineers has years of experience and expertise, which enables us to handle any project, from simple to complex, with unmatched precision and quality. At Metal Craft Machining, we are committed to providing our customers with world-class products and services. Our CNC machining services are continuously evolving with the latest technological advances to meet our customers' changing needs. We have invested in the latest equipment and technology, including CAD/CAM software and other tools, to ensure that we can offer our customers the best possible solutions.

CNC machining services are engineered to provide world-class products with unmatched quality, and our value-added services give us the flexibility to integrate many additional services, from our domestic or low-cost factories, with our precision machining and manufacturing to give our customers what they need from one supplier. Our diverse equipment set, combined with our team of skilled machinists and engineers, enables us to handle any project, from simple to complex, with unmatched precision and quality. We are committed to providing our customers with the best possible solutions and ensuring that we meet their unique requirements.

Redundancies Between Factories

In the world of CNC machining, redundancies refer to having multiple factories that can perform the same operations, processes, or tasks. The main purpose of having redundancies in a CNC factory is to ensure that all of the customer's requirements are met without any delay or interruption. CNC companies understand that their customers have varying needs and requirements, which is why they invest in redundant equipment and processes to ensure that they can handle any project, regardless of its complexity.

One of the primary redundancies needed in our business model is to have multiple factories that all use the same equipment and software. This redundancy ensures that if one factory fails, there is another factory with the same machine that can pick up the slack, reducing downtime and ensuring that the project remains on schedule.

Working with Metal Craft Machining, which has redundant factories both in the U.S. and Asia, is beneficial as we can provide several unique advantages for our customers. These include:

- Improved flexibility: Customers can choose to have products manufactured in the facility that is most advantageous and that offers the most favorable pricing, depending on their specific needs.

- Reduced lead times: Having facilities in both the USA and Asia can reduce lead times for customers, which is especially beneficial for customers who require products on short notice or have tight deadlines.

- Consistent quality: Because we have implemented the same quality control standards and manufacturing processes in each facility, we can ensure that customers receive products that meet their exact specifications, regardless of where they are manufactured.

- Reduced risk: CNC machining companies can reduce their risk in the event of quality issues or other disruptions such as natural disasters or geopolitical events that may impact one region but not the other. This redundancy can help ensure business continuity and minimize disruptions to customers.

Custom CNC Machining Process & Capabilities

- Turning (Contour, Form, Taper, Straight)

- Facing

- High Speed Drilling

- Boring

- Slotting

- Reaming

- Rotary Broaching

- Threading

- Counterboring

- Countersinking

- Pocketing

- Profiling

- Reaming

- Tapping

- Thread Milling

- Knurling

- Grinding

- Polishing

- Hexing

- Swiss Style CNC Machining

- Sawing - Vertical and Horizontal

Large Format CNC Milling

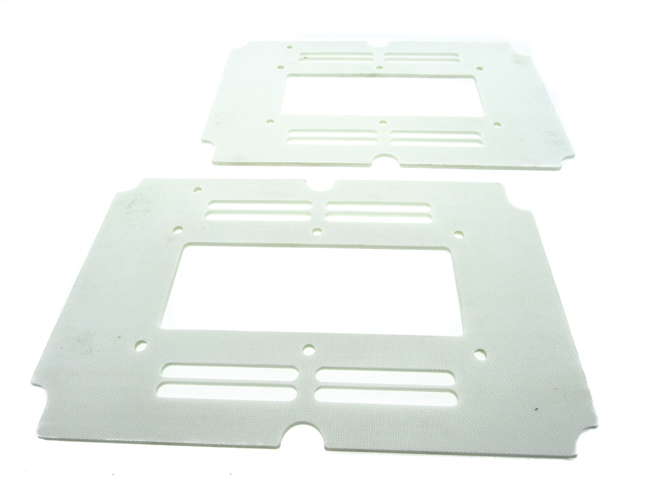

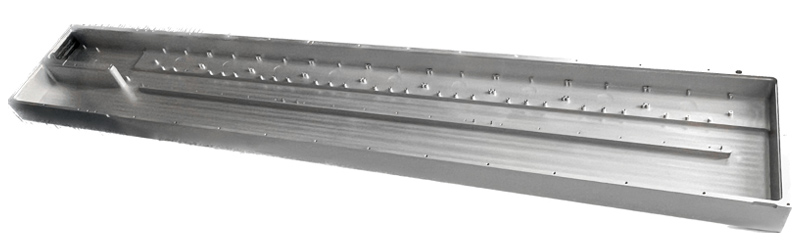

One of the standout capabilities of Metal Craft Machining is our advanced CNC milling technology. We utilize high-precision, multi-axis CNC machines equipped with large working envelopes, enabling the production of parts that reach up to 48 inches in length. These machines are meticulously calibrated to ensure accuracy, repeatability, and superior surface finishes.

Additionally, our team of skilled engineers and machinists possess a deep understanding of material properties and machining techniques. This knowledge enables us to optimize toolpaths, select the appropriate cutting tools, and determine ideal feeds and speeds for milling operations on large format parts which is a very different task than when creating programs to mill smaller parts. Our commitment to quality control and adherence to tight tolerances ensures that every part produced meets or exceeds industry standards.

Furthermore, we are versatile in working with a wide range of materials, from metals to plastics and composites, making them a versatile solution for various industries. Their dedication to innovation and investment in the latest CNC milling technology keeps them at the forefront of precision manufacturing, making them an ideal partner for projects requiring parts of significant length and complexity.

Value Added Services

Our value-added services give us the flexibility to integrate many additional services with our precision machining and manufacturing to give our customers what they need from one supplier.

- Assembly

- Sub-Assembly

- Kitting

- Painting

- Heat Treating

- Plating

- Bead Blast

- Anodizing

- Powder Coat

- Silk Screening

- Passivation

- Laser Cutting

- Waterjet Cutting

Part Size Dimensional Limitations:

- Max diameter - 3/4”

- Max length - 23”