Industrial Sensors

Computer Numerically Controlled (CNC)-machined products are used in a wide range of industrial sensors, as we can offer precise and accurate manufacturing capabilities and tolerances. Metal Craft Machining has over 30 years of experience in designing and producing high-mix, medium-volume parts for the industrial sensor industry.

Industrial sensors are used to detect and measure different parameters, such as temperature, pressure, humidity, and vibration, so their accuracy depends upon how each component is manufactured. These sensors play a crucial role in ensuring the smooth and exacting operation of various industries, including manufacturing, energy, and transportation.

CNC-machined products play a significant role in the production of industrial sensors, providing precise and accurate manufacturing capabilities that are crucial to ensuring reliable and consistent sensor operation. From housing and casings to electrical components and sensing elements, CNC machining enables the production of custom-made components that meet the specific requirements of each sensor type.

Applications For Industrial Sensors

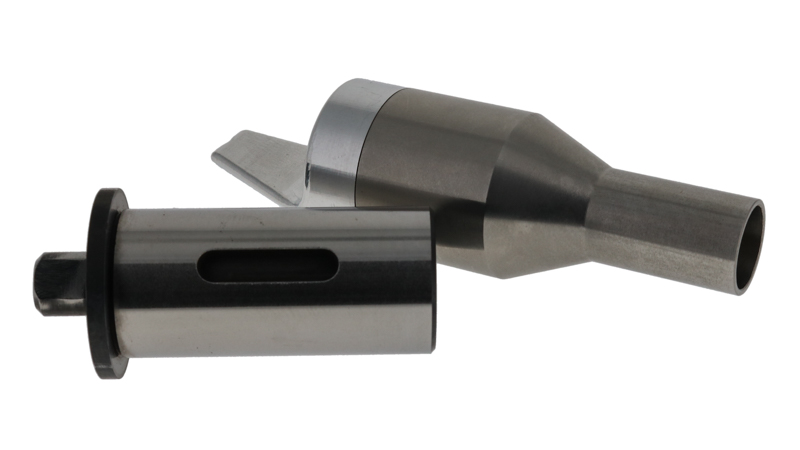

Sensor Housing and Casings

One of the most significant applications of CNC-machined products in industrial sensors is in the production of sensor housing and casings. These components are usually made from materials such as stainless steel, aluminum, or plastic and require precise dimensions and surface finishes. CNC machining allows for the production of complex shapes and geometries, providing manufacturers with the flexibility to design and produce custom-made housing and casings that meet the specific requirements of their sensors.

Connectors, Pins, and Terminals

Another application of CNC-machined products in industrial sensors is in the production of electrical components, such as connectors, pins, and terminals. These components are used to connect the sensors to the control system and require high precision to ensure reliable and stable operation. CNC machining can achieve tight tolerances and produce components with consistent dimensional accuracy, ensuring proper connection and signal transmission.

Pressure Sensing

In the field of pressure sensing, CNC-machined products play a crucial role in the production of pressure transducers. These devices are used to measure pressure changes in a variety of industrial processes, such as in pipelines, vessels, and reactors. CNC-machined components, such as diaphragms and pressure ports, are critical components of pressure transducers and require precise dimensions and surface finishes to ensure accurate pressure measurement.

Temperature Sensors

CNC-machined products are also used in the production of temperature sensors, such as thermocouples and Resistance Temperature Detectors (RTDs). These sensors require high precision in the manufacture of their sensing elements and terminal blocks. CNC machining enables the production of components with consistent dimensional accuracy, ensuring reliable and accurate temperature measurement.

Vibration Sensors

Another application of CNC-machined products in industrial sensors is in the production of vibration sensors. These sensors are used to detect and monitor vibration levels in a wide range of industrial equipment, including motors, pumps, and turbines. CNC machining enables the production of components with high precision and dimensional accuracy, ensuring reliable and consistent vibration measurement.

Optical Sensors

CNC-machined products are used in optical sensors in several ways as the accuracy, consistency, and precision of CNC-machined products make them an essential component in the design and production of optical sensors:

- Housing and Mounting: The precise and consistent tolerances achieved through CNC machining make it possible to produce housing and mounting systems for optical sensors that provide a secure and stable base for the sensor's components.

- Lens Holders: CNC-machined products are used to hold and position lenses that focus the light collected by the sensor, which is then translated into data.

- Prisms: CNC-machined prisms are used in optical sensors to split, reflect, or refract light in specific directions, which is critical in the functioning of the sensor.

- Light Pipes: CNC-machined light pipes are used to guide light from the sensor to the electronics that process the data.

- Mirrors: CNC-machined mirrors are used in optical sensors to redirect light in a precise manner, helping to achieve accurate results.

Overall, the accuracy, consistency, and precision of CNC-machined products make them an essential component in the design and production of optical sensors.

Flow Sensors

CNC-machined products play a critical role in the production of flow sensors, such as ultrasonic and magnetic flow sensors. These sensors require precise and consistent dimensional accuracy in the production of their sensing elements and housings. CNC machining can produce components with high precision, ensuring accurate flow measurement, and reliable performance.