Industrial Instruments

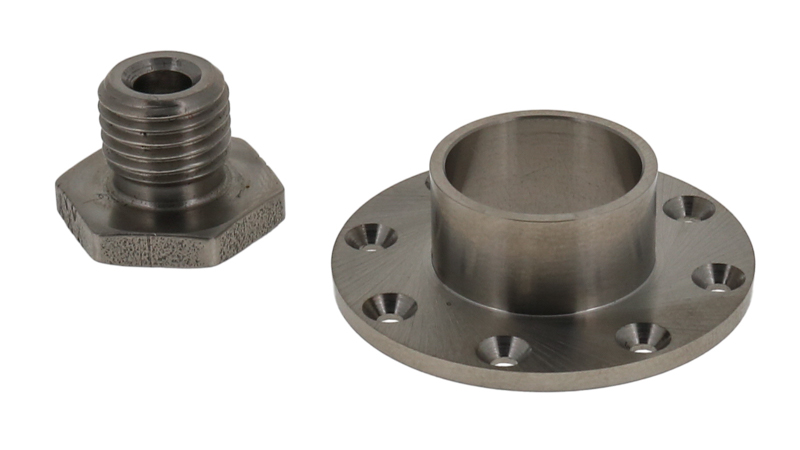

Computer Numerical Control (CNC)-machined parts are essential components in high-precision industrial instruments/equipment. These parts are used to create highly accurate and precise instruments that are used in a variety of industries, including aerospace, semiconductor test, medical, and industrial instruments. The use of CNC-machined parts in high-precision industrial instruments has several advantages that make it the preferred method for manufacturing these components.

Benefits Of Using CNC-Machined Parts

One of the main benefits of using CNC-machined parts in high-precision industrial instruments is the level of precision that can be achieved. CNC machines are able to produce parts with very tight tolerances and accuracy to within a few thousandths of an inch. This level of precision is essential for many high-precision instruments, such as those used in medical or aerospace applications.

Tolerances

For example, the tolerances of 5-axis CNC milling depend on several factors, including the specific machine, the material being machined, the cutting tools being used, and the type of operation being performed. 5-axis CNC milling can achieve tolerances in the range of 0.001 inches to 0.005 inches, depending on the application.

For more demanding applications, tighter tolerances of 0.0001 inches to 0.001 inches may be required. In these cases, specialized cutting tools and high-precision machines may be used to achieve these tight tolerances. It is important to note that the tolerances achieved in 5-axis CNC milling can also be influenced by the machining strategy, such as the cutting speed, feed rate, and tool path. A good machining strategy can help to achieve the desired tolerances while reducing the risk of defects or tool breakage.

Speed

Another benefit of CNC-machined parts is the speed at which they can be produced. With the ability to program the machine to perform a specific operation multiple times, CNC machining can produce large quantities of parts quickly and efficiently. This speed is particularly important for industries that require large quantities of precision components, such as the aerospace and automotive industries.

Flexibility

CNC machining also offers a high level of flexibility. The machines can be programmed to produce a wide range of shapes and sizes, making it possible to create custom parts for specific applications. This flexibility allows engineers and designers to create unique and innovative instruments that meet specific requirements.

Repeatability

In addition to its precision and flexibility, CNC machining also offers a high level of repeatability. This means that each part produced will be the same, making it possible to produce large quantities of parts with consistent accuracy and precision. This is particularly important for industries where the instruments are used for critical applications, such as the medical or aerospace industries.

Key Advantages for Industrial Instruments

One of the key advantages of CNC machining is its use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This software allows engineers and designers to create and simulate the production process, making it easier to identify and resolve any potential problems before the actual machining takes place. This not only saves time, but it also helps to ensure that the final product meets the desired specifications.

CNC-machined parts are also highly durable and long-lasting. This is because the process of CNC machining involves the removal of material from a solid block, which results in a strong and rigid part. This durability is essential for high-precision instruments, as they need to be able to withstand the demands of their specific applications.

Another advantage of CNC machined parts is their compatibility with a variety of materials. CNC machines can be used to process a wide range of materials, including metals, plastics, composites, and wood. The material selection will depend on the specific requirements of the application, making it possible to create high-precision instruments that are made from the most appropriate materials.

Specific equipment/instruments Metal Craft Machining has experience with:

- Robotics

- Printing Equipment

- Braiding Machines

- Pumps & Valves

- Finishing of Castings

- Cutting and Bending Equipment

- Wire Drawing

- Laser Welding/Water Jet Cutting

- And many others…

CNC-machined parts play a critical role in the production of high-precision industrial instruments. With its precision, speed, flexibility, and repeatability, CNC machining offers a number of advantages over traditional manual machining methods. By using CNC machined parts, industries are able to produce high-quality and precise instruments that are essential for their specific applications.