Equipment Investments

At Metal Craft Machining, one of our core values is to reinvest heavily into our equipment, software, and people to ensure that we can continue to deliver the highest quality machined parts in North America.

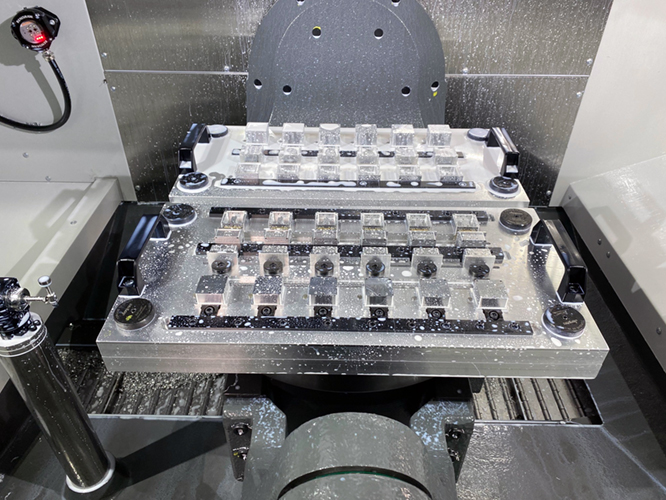

Haas UMC-750 – High-Precision 5-Axis CNC Milling Machine

The Haas UMC-750 is a 5-axis universal machining center designed for high-precision, high-efficiency machining of complex parts. With its robust construction, advanced motion control, and simultaneous 5-axis capabilities, this machine is ideal for industries requiring tight tolerances and superior surface finishes, such as aerospace, medical, automotive, and precision manufacturing.

Key Capabilities:

- Simultaneous 5-Axis Machining: Enables efficient machining of intricate geometries with fewer setups, reducing cycle times and increasing accuracy.

- Large Work Envelope: Handles parts up to 30" x 20" x 20" (762 x 508 x 508 mm), accommodating a wide range of applications.

- High-Speed Spindle: Operates up to 10,000 RPM, ensuring smooth surface finishes and optimal cutting speeds.

- Advanced Motion Control & High Rigidity: Minimizes vibration and ensures stability for consistent, repeatable precision.

- Exceptional Tolerance Control: Capable of holding tolerances as tight as ±0.0002" (±0.005 mm), ensuring extreme accuracy in critical applications.

- Integrated Trunnion Table: Provides full 5-axis movement for machining complex angles and contours in a single setup.

With its high-speed performance, superior accuracy, and advanced 5-axis capabilities, the Haas UMC-750 is an ideal solution for manufacturers seeking efficiency, precision, and versatility in complex part production.

Watch It In Action

See how a 5-axis CNC mill works with custom tooling in order to make high tech parts cost effectively.

Milling:

- CNC 3 axis VMC

- CNC 4 axis VMC

- CNC 5 axis UMC (equipped w/Renishaw probe system for in machine part setup and in-process inspection)

- Three axis knee mills w/digital controls (secondary ops)

Milling maximum axis capacity = X/60" x Y/40" x Z/30"

Turning:

- CNC turning centers (3" thru capacity, 9" max capacity)

- Swiss screw lathe (.625" OD capacity)

ID/OD grinding, up to 3" capacity

Surface grinding, up to 9"x9"

Tsugami S206-II – High-Precision 7-Axis CNC Lathe

The Tsugami S206-II is a 7-axis Swiss-type CNC lathe engineered for high-precision, high-speed machining of small, complex components. Designed for industries that demand extreme accuracy, such as medical, aerospace, electronics, and precision manufacturing, this machine combines advanced multi-axis capabilities with superior rigidity and performance.

Key Capabilities:

- 7-Axis Simultaneous Machining: Allows for complex part geometries with minimal setups, reducing cycle times and improving efficiency.

- Swiss-Type Lathe Design: Optimized for machining small-diameter parts with unparalleled accuracy and surface finishes.

- Dual Spindle Operation: Enables seamless part transfers, allowing for complete machining in a single process.

- Live Tooling for Milling, Drilling & Tapping: Eliminates the need for secondary machining, reducing production time.

- Exceptional Tolerance Control: Capable of holding tolerances as tight as ±0.0001" (±0.0025 mm), ensuring extreme precision and repeatability.

- High-Speed & Rigid Construction: Reduces vibration for improved tool life, consistent accuracy, and superior surface finishes.

With its ability to perform multiple operations in a single setup while maintaining ultra-tight tolerances, the Tsugami S206-II is the ideal solution for intricate, high-precision components, delivering exceptional efficiency, accuracy, and repeatability for demanding manufacturing environments.

DMG Mori Seki ZT1500YB – High-Precision 8-Axis Turning & Milling Center

The DMG Mori Seki ZT1500YB is a state-of-the-art 8-axis dual turret turning and milling center, designed for a high-precision, high-efficiency machine. This advanced machine integrates turning and milling operations, allowing for the complete machining of complex parts in a single setup, reducing cycle times and increasing productivity.

Key Capabilities:

- 8-Axis Machining: Simultaneous multi-axis control enables intricate part geometries and high-precision machining.

- Dual Turret Configuration: Allows simultaneous machining on both spindles, dramatically reducing production time.

- High-Speed Spindles: Ensures superior surface finishes and high cutting performance on ferrous and non-ferrous materials.

- Live Tooling & Y-Axis Milling: Enables drilling, tapping, and milling operations directly on the lathe, eliminating secondary machining steps.

- Twin Spindles: Facilitates seamless part hand-off between spindles for complete part machining without repositioning.

- Rigid Construction: Designed for stability and precision, ensuring tight tolerances for aerospace, medical, and industrial applications.

With its combination of turning, milling, and multi-tasking efficiency, the ZT1500YB enhances production speed, accuracy, and cost-effectiveness, making it an ideal choice for high-precision, complex parts manufacturing.

Siemens NX

Siemens NX is a very advanced, high-end CAD/CAM/CAE software used in CNC (Computer Numerical Control) machining as a comprehensive solution for the design, simulation, and manufacturing of products. It helps to automate the entire manufacturing process and increase efficiency in the production line.

NX offers a complete set of tools for product design, engineering analysis, manufacturing, and simulation. The software supports a range of design and engineering processes, including 3D modeling, assembly design, and finite element analysis. It also provides tools for machining and CNC programming, as well as for digital mockup and simulation. Additionally, NX features a powerful data management system that helps users manage and organize product data throughout the product development process.

NX is known for its robust capabilities, flexible modeling environment, and highly integrated software ecosystem. It is also praised for its ability to handle large and complex designs, as well as its support for industry standards and data interoperability.

Some of the CNC-focused parts of the software include:

- Design and Modeling: Siemens NX software provides a 3D modeling environment for creating and designing components for machining. It supports various file formats and allows for the integration of CAD and CAM data.

- Simulation: The software has built-in simulation capabilities that allow for the testing of machining processes before actual production. This helps to identify any potential problems and make necessary adjustments to improve the machining process.

- CNC Programming: Siemens NX software has a user-friendly interface that makes it easy to create CNC programs. It has advanced features like a powerful post-processor and CAM functions that streamline the programming process.

- Machining Process Optimization: Siemens NX software provides tools for optimizing cutting parameters, reducing production time and costs, and improving surface finish and accuracy.

- Machine Monitoring: The software provides real-time monitoring of CNC machines, allowing manufacturers to track and optimize machine performance, reduce downtime, and improve overall productivity.

Metal Craft Machining made this significant investment several years ago to provide our customers with best-in-class service. Having this software allows us to machine more complex parts faster, so that we can provide our customers with not only their repeat production parts but their prototypes as well.

Quality Equipment

5D OMM

A 5D optical measurement machine is a precision measurement instrument that uses optical lasers to measure a variety of physical characteristics of a CNC machined part. The "5D" designation typically refers to the five dimensions of measurement that the machine can perform: length, width, height, depth, and angles.

3D CMM

A 3D coordinate measuring machine (CMM) is a measuring device that measures the geometry of objects by establishing discrete points on a physical surface using a contact probe. The machine will specify the probe's position in terms of displacement from an origin point in a three-dimensional coordinate system (XYZ axes).

CCD

CCD laser measurement system is a high-accuracy semiconductor-based triangulation measurement system with 1.0-micron resolution. The system uses a high-resolution CCD (Charge-coupled device) sensing array that provides measurement precision.

Laboratory Testing Equipment

Abrasion Tester

RCA Tester

Poach Tester

Degree of Finish Tester

Drawing Tester

Electrical Property Tester

Film Thickness Tester

Resistance Tester

Magnetic Stirring Apparatus Tester

Hardness Tester

Vibration Wear Tester

Salt Spray Tester

Constant Temperature and Humidity Tester

Constant Temperature Incubator Tester