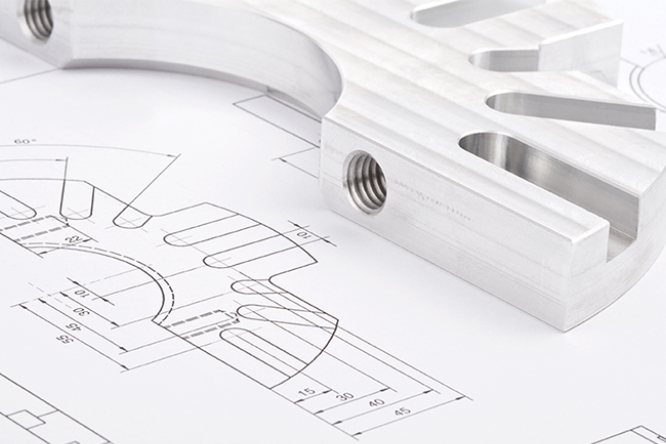

Over 30 Years Experience In Manufacturing Precision Parts

Machined metal and plastic parts for a wide variety of industries.

Metal Craft Machining has over 30 years of experience in manufacturing precision parts to our customer’s exact specifications. With 3-axis, 4-axis, or 5-axis milling machines along with CNC lathes, turning centers, and vertical milling machines, the professional CNC engineers at Metal Craft have machined parts for a wide variety of industries. Our team is positioned to move quickly to produce small volume runs with very tight tolerances along with providing competitive production utilizing automation and lean production techniques.

Global Supply Chain

With over 5,000 active customers, Epec has developed and excelled at managing a global supply chain. Through our HQ outside of Boston, our logistics and engineering staff oversee our 30+ person team in Shenzhen, China who manage our day-to-day requirements along with our transfer hub in Hong Kong where all of our factories manage shipment to the USA.

One PO For a Fully Finished Part

With decades of experience in managing every aspect of a finished CNC machined part, we work with customers so that they can issue one PO and get a fully finished part back that can go right into production. This means that we manage everything from the basic machining, surface finish (paint, plating, anodizing, etc.), assembly, kitting, and any other needed requirements. Our approved vendor portfolio allows us to save the customer both time and money by only having to manage one purchase order with one supplier.

Additional Services

Engineering

We combine extensive manufacturing experience with in-house mechanical engineering resources to help our customers develop a metal or plastic product to their exact requirements.

Speed

Our goal is to have the best lead times in the industry and our staff is committed to being flexible to help us meet customer demands. Even our manufacturing lead times from Asia are under 20 working days.

Inventory Management

We support customers by holding completed inventory so that we can quickly respond to our customer’s needs without customers having to have all the inventory on their books.